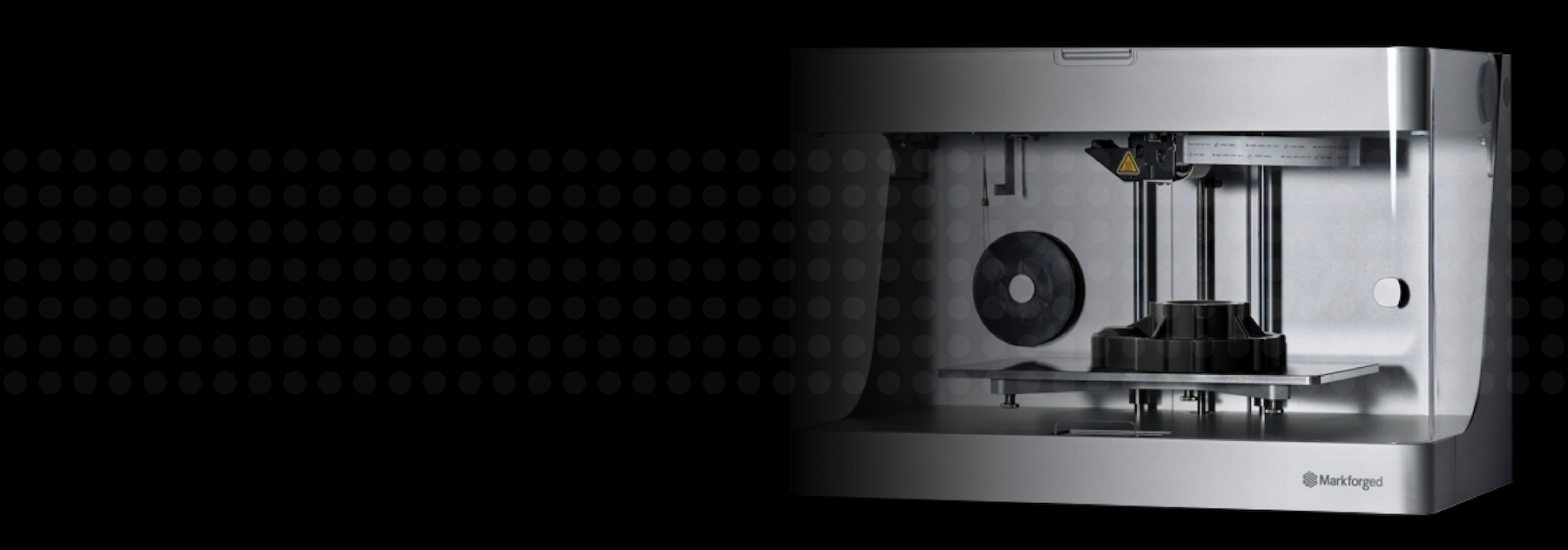

Markforged Mark Two

Machine Zone

3D Printer

Take a closer look at the Markforged Mark Two in action (opens in new tab).

Why you'll love this machine

The Mark Two 3D printer was developed to overcome the strength limitations inherent in many 3D printing materials. It's the world’s first 3D printer to print composites, allowing you to create functional parts, tools and prototypes with a better strength-to-weight ratio than ever before - all in the shortest possible time.

How it works

The Mark Two uses FFF (Fused Filament Fabrication) which combines an outer layer of nylon base material Onyx fortified with high-strength continuous carbon fibre, Kevlar® or fibreglass. The machine alternates between two nozzles during the printing process, producing incredibly robust fibre-reinforced plastic parts in a single construction process. This continuous fibre printing technology is called Continuous Filament Fabrication (CFF).

How to book the Markforged Mark Two

It's easy as 1-2-3 to get working on the Mark Two, which includes machine-specific training, file preparation on the proprietary EIGER software and finally, printing and finishing time.

Click here to view a step by step guide to booking this machine.

Ready to book but not yet a Member? Here's how to get started.

Current Members can book via the Dashboard.

| Price List |

|---|

|

Training Booking |

| Technical Spec |

|---|

| Weight - 28kg |

| Dimensions - 57.5 x 32.2 x 36.6 cm |

| Materials - Onyx, Fibreglass, Carbonfibre, Kevlar |

| Layer Thickness - 0,1 mm bis 0,2 mm |

| Nozzle Diameter - FFF-Nozzle 0,4 mm; CFF-Nozzle 0,9 mm |

| Extruder Units - Double-quick-extruder |

| Print Pause Restart - Yes |

| Software - EIGER (cloud-based) |